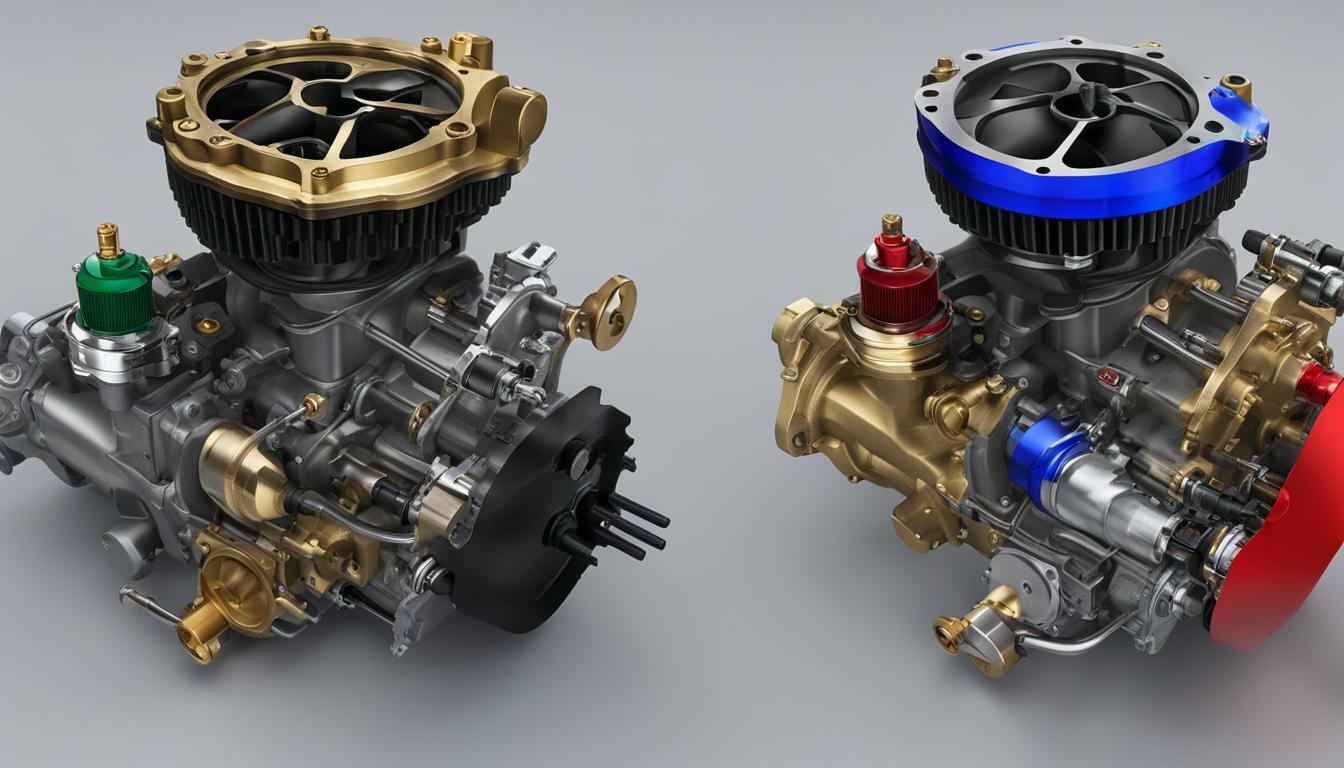

When it comes to fuel injection systems in modern vehicles, two technologies stand out – traditional carburetors and direct injection systems. These systems differ in significant ways, from how they function to their impact on fuel efficiency and engine performance.

In this article, we’ll explore the difference between traditional carburetors and direct injection systems, examining the mechanics and benefits of each technology. Whether you’re a car enthusiast or curious about how your vehicle works, read on to learn more!

Key Takeaways:

- Traditional carburetors and direct injection systems differ in their mechanics and functions.

- Carburetors work by mixing fuel and air, while direct injection systems deliver fuel directly to the combustion chamber.

- Direct injection systems contribute to improved fuel efficiency and engine performance, while reducing emissions.

Mechanics of Traditional Carburetors

Traditional carburetors work by creating a mixture of air and fuel that’s drawn into the engine’s cylinders. The carburetor’s primary function is to atomize the fuel into tiny droplets to ensure efficient combustion. Fuel atomization is the process of breaking fuel into small droplets to increase its surface area, which provides a higher chance of igniting. Once the fuel and air mixture is created, the carburetor sends it through the intake manifold and into the engine’s cylinders, where it ignites to power the vehicle. Traditional carburetors are typically found in gasoline engines, as they’re highly effective at providing the necessary fuel-to-air ratio.

One of the major advantages of traditional carburetors is their simplicity and low cost. They’re easy to install and maintain, making them a popular choice for many automotive manufacturers. Additionally, traditional carburetors provide good performance at low to moderate engine speeds. However, they may not be as efficient as direct injection systems in terms of fuel atomization and combustion efficiency.

The downside of traditional carburetors is their tendency to waste fuel due to their inability to deliver precise amounts of fuel. The engine must work harder to compensate for the inconsistencies, leading to reduced fuel efficiency and increased emissions.

Mechanics of Direct Injection Systems

Direct injection systems deliver fuel directly into the combustion chamber. Compared to traditional carburetors, this process enhances fuel atomization and combustion efficiency, resulting in improved engine performance.

The main components of direct injection systems include:

| Component | Description |

|---|---|

| High-pressure fuel pump | Pumps fuel at high pressure, typically between 500 to 2,000 PSI, to the fuel rails. |

| Fuel rails | Distribute high-pressure fuel to each injector. |

| Injectors | Inject fuel directly into the combustion chamber. |

Direct injection systems offer several advantages over traditional carburetors. They improve engine performance, as the fuel is injected directly into the combustion chamber, resulting in better fuel atomization and a more efficient combustion process. This process leads to increased power output, improved fuel economy, and reduced emissions.

Direct injection systems also offer automakers more design flexibility, allowing them to create engines with higher compression ratios, and therefore more power, without compromising fuel efficiency. Additionally, direct injection systems can operate with a leaner air-fuel mixture, resulting in even greater fuel efficiency.

Overall, the mechanics of direct injection systems make them a superior choice for those seeking improved engine performance and fuel efficiency.

Fuel Efficiency Comparison

When it comes to fuel efficiency, the difference between traditional carburetors and direct injection systems is significant. Direct injection systems offer superior combustion efficiency, which translates directly into increased fuel efficiency. Direct injection systems utilize high-pressure fuel pumps to deliver fuel directly into the combustion chamber. This enhanced fuel delivery method allows for better atomization, or finer fuel mist, resulting in more complete combustion. In contrast, traditional carburetors use a less precise method of fuel delivery, which can result in incomplete combustion and wasted fuel.

Furthermore, direct injection systems can contribute to fuel savings in alternative fuel systems. As alternative fuels, such as ethanol, have lower energy content than gasoline, direct injection systems can compensate for this with their superior combustion efficiency. This means that even with lower energy content, alternative fuels can still achieve comparable fuel efficiency to gasoline when used in direct injection systems.

In summary, the fuel efficiency comparison between traditional carburetors and direct injection systems clearly favors the latter. With enhanced combustion efficiency and the potential for fuel savings in alternative fuel systems, direct injection technology represents a significant step forward in automotive technology.

Benefits of Direct Injection Systems

Direct injection systems offer numerous benefits that make them an attractive option for modern vehicle manufacturers. One of the biggest advantages of direct injection systems is improved fuel efficiency. These systems inject fuel directly into the combustion chamber, resulting in better fuel atomization and combustion efficiency. This leads to lower fuel consumption and reduced emissions, making them an eco-friendly choice for today’s drivers.

In addition to enhancing fuel efficiency, direct injection systems also contribute to improved engine performance. By delivering fuel directly to the combustion chamber, these systems can produce a more even and complete burn, resulting in a more powerful and responsive engine. As a result, vehicles equipped with direct injection systems can deliver a smoother and more satisfying driving experience.

Furthermore, direct injection systems can be adapted to work with a variety of different fuel types, including diesel and alternative fuel systems. This makes them a versatile choice for manufacturers looking to optimize fuel efficiency and performance across a range of different vehicles and operating conditions.

In summary, the benefits of direct injection systems are clear. With improved fuel efficiency, enhanced engine performance, and a greater capacity for fuel adaptation, these systems offer numerous advantages over traditional carburetors.

Conclusion

After exploring the fundamental differences between traditional carburetors and direct injection systems, it is evident that adopting the latter technology provides numerous benefits.

Enhanced Fuel Efficiency

Direct injection systems allow for precise fuel delivery, significantly improving combustion efficiency. This results in a reduction of fuel consumption, equating to cost savings and reduced environmental impact.

Improved Engine Performance

By delivering fuel directly into the combustion chamber, direct injection systems contribute to improved engine performance. This translates to increased power, smoother acceleration, and a more responsive driving experience.

Reduced Emissions

Direct injection systems reduce emissions of pollutants such as carbon dioxide, carbon monoxide, and nitrogen oxides. This is because these systems allow for better control over the amount of fuel burned, resulting in more complete combustion and fewer byproducts.

Overall, the benefits of direct injection systems make them a clear choice for modern automotive development. However, it is important to note that traditional carburetors still have their place in certain applications, particularly those involving alternative fuels.

By understanding the mechanics, functions, and benefits of each system, readers can make informed decisions when it comes to optimizing fuel efficiency and improving engine performance. As technology continues to progress, it will be interesting to see what advancements are made in fuel delivery systems and how they shape the future of the automotive industry.

FAQ

Q: What is the difference between traditional carburetors and direct injection systems?

A: Traditional carburetors deliver fuel to the engine by mixing it with air in a carburetor before entering the combustion chamber. Direct injection systems, on the other hand, inject fuel directly into the combustion chamber. This direct method allows for better fuel atomization and improved combustion efficiency.

Q: How do traditional carburetors work?

A: Traditional carburetors work by utilizing a series of air and fuel passages to mix the fuel with air before it enters the combustion chamber. These systems rely on the vacuum created by the engine to draw fuel into the engine’s intake manifold.

Q: How do direct injection systems work?

A: Direct injection systems work by injecting fuel directly into the combustion chamber at high pressure. This precise delivery method allows for better fuel atomization, resulting in improved combustion efficiency and engine performance.

Q: Which is more fuel-efficient, traditional carburetors or direct injection systems?

A: Direct injection systems are generally more fuel-efficient than traditional carburetors. The direct injection method improves combustion efficiency, leading to better fuel economy. However, it’s important to note that other factors, such as engine design and driving conditions, also play a role in overall fuel efficiency.

Q: What are the benefits of direct injection systems?

A: Direct injection systems offer several benefits. They contribute to enhanced fuel efficiency, improved engine performance, and reduced emissions. The precise fuel delivery of direct injection systems results in better combustion, leading to more power and fewer emissions.

Skip to main content

Skip to main content